Contact us

Email:

service@steelplatewaterstop.com

Tel : +8618731764741

Tel : +8615613788619

Address : Guozhuang Town, Xianxian County, Cangzhou City, Hebei province

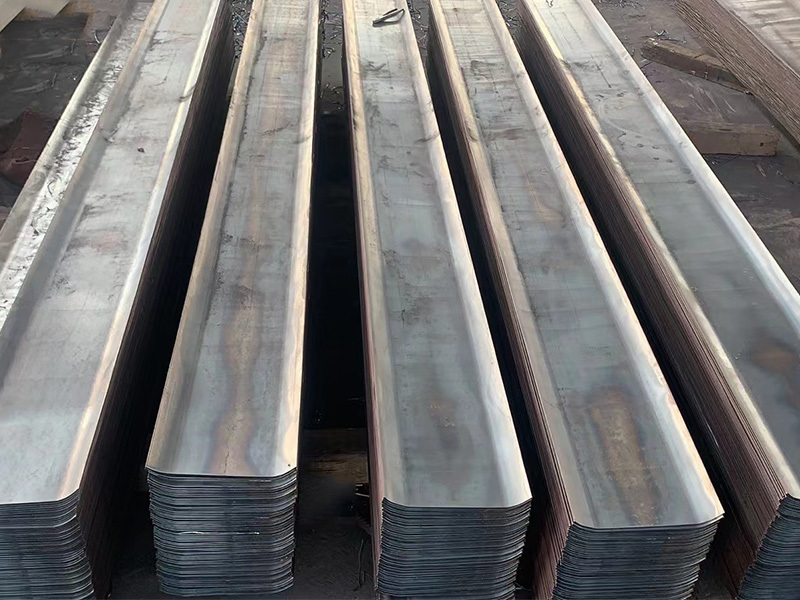

To draw custom shaped steel plate

Category:

- Related products

-

Clear customization requirements

Before customizing the stainless steel sealing plate, it is first necessary to clarify the specific needs, including the size, thickness, material requirements of the sealing plate (such as 304, 316 and other stainless steel materials), surface treatment requirements (such as polishing, drawing, etc.), and whether special processing is required (such as bending, drilling, etc.). These needs will directly affect the customized program and cost of the water stop plate.

Select supplier

It is important to choose an experienced and reputable stainless steel sealing plate supplier. Through Internet search, industry recommendation or field visit, you can understand the supplier's qualification, production capacity, product quality and service level. When choosing, you can focus on the following aspects of the supplier:

Production capacity: Ensure that suppliers have sufficient production capacity to meet custom requirements.

Product quality: Check the supplier's product quality certification and past customer reviews to understand the stability and reliability of their products.

Service level: Understand the supplier's service process and support before, during and after sale.Customization scheme determination

After communicating with the supplier, determine the customized plan according to the actual needs. This includes the size of the sealing plate, material selection, surface treatment requirements and special processing requirements. At the same time, it is also necessary to determine the delivery time, price and other key terms.

Production and processing

After the customized plan is determined, the supplier will produce and process according to the requirements. This includes a series of processes such as raw material procurement, cutting, bending, welding, and surface treatment. In the production process, the supplier should strictly control the quality to ensure that the water seal meets the relevant standards and requirements.

Quality inspection and acceptance

After the production is completed, the supplier will conduct quality inspection on the sealing plate. This includes dimensional inspection, surface quality inspection, performance testing and many other aspects. After ensuring that the water stop meets the customized requirements and relevant standards, it will be packed and shipped. After receiving the sealing plate, the recipient should also carry out acceptance work to ensure that the product is correct.

After-sales service

In the process of use, if you encounter any problems or need technical support, the supplier should provide timely after-sales service. This includes product consultation, troubleshooting, maintenance and replacement. Good after-sales service will provide customers with better experience and protection.

Matters needing attention

In the customization process, we should ensure that we maintain close communication with suppliers and timely feedback on requirements and problems.

Pay attention to the selection of stainless steel material and thickness suitable for engineering needs to ensure the water sealing effect and service life.

During the acceptance process, the size, surface quality and performance of the sealing plate should be carefully checked to ensure that the product meets the requirements.

Tags:

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Related products