2024-08-01

Construction points of steel plate water stop belt

Location selection: We should try our best to ensure that the water sealing plate is on the middle line of the wall to ensure its waterproof effect.

Welding quality: The welding between two steel plates should be full and double-sided welding, and the lap length is not less than 20mm to avoid leakage affecting the waterproof performance.

2024-08-01

Working principle of steel plate water stop belt

The working principle of the steel plate water stop belt is based on its material characteristics and installation position. When the lower concrete is poured, a certain size of steel plate water stop belt is embedded, part of which is exposed outside. The next time the concrete is poured, this part of the steel plate is poured in together to form a waterproof barrier. When the external water pressure acts on the steel plate water stop belt, the water penetration can be effectively prevented due to the rigidity of its material and the tight adhesion with the concrete.

2024-08-01

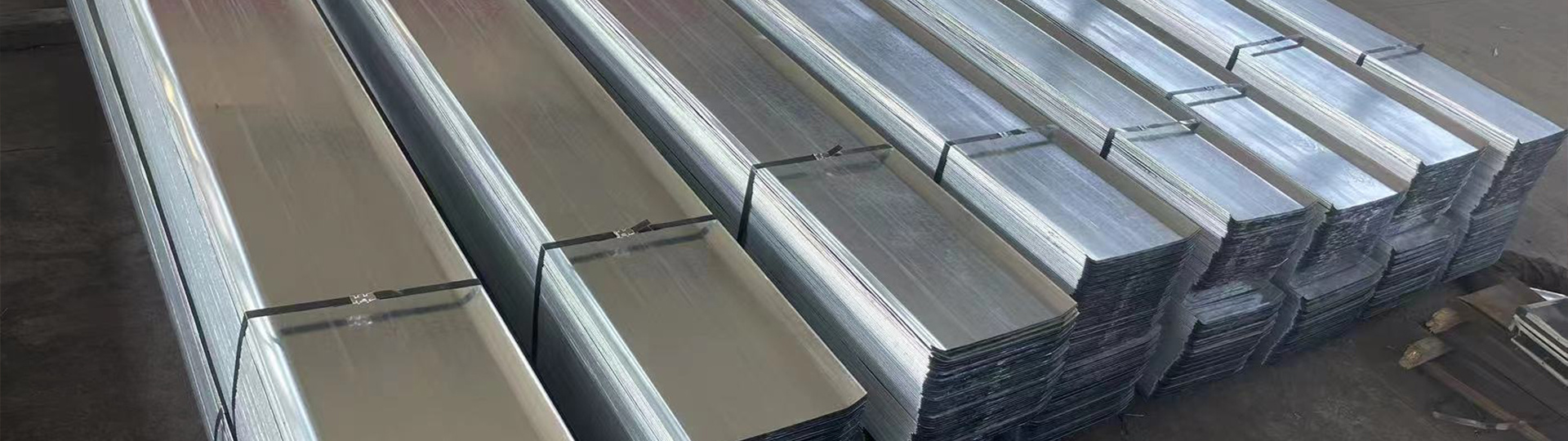

Specifications of steel plate water stop belt

Material: Steel plate water stop belt is generally made of cold rolled plate, galvanized plate, stainless steel plate and other materials. Among them, the good bonding between galvanized steel plate and concrete makes the waterproof performance better.

Specifications: Common specifications include 2002, 2003, 3002, 3003, 3502, 3503, 4004, 3305 and so on. These specifications can be customized to meet specific engineering needs.

Definition and use of steel plate water stop belt

Definition: Steel plate water stop belt is a waterproof material made of cold-rolled plate or other metal plate (such as copper plate, alloy steel plate) as the base material.

Usage: Mainly used in reinforced concrete structures, DAMS, basements, tunnels, subways and other large projects to change the water penetration path, extend the water penetration route, and play a role in corrosion resistance.

01

2024/08