Contact us

Email:

service@steelplatewaterstop.com

Email:

service@steelplatewaterstop.com

Tel : +8618731764741

Tel : +8615613788619

Address : Guozhuang Town, Xianxian County, Cangzhou City, Hebei province

After the production is completed, the supplier will conduct quality inspection on the sealing plate. This includes dimensional inspection, surface quality inspection, performance testing and many other aspects. After ensuring that the water stop meets the customized requirements and relevant standards, it will be packed and shipped. After receiving the sealing plate, the recipient should also carry out acceptance work to ensure that the product is correct.

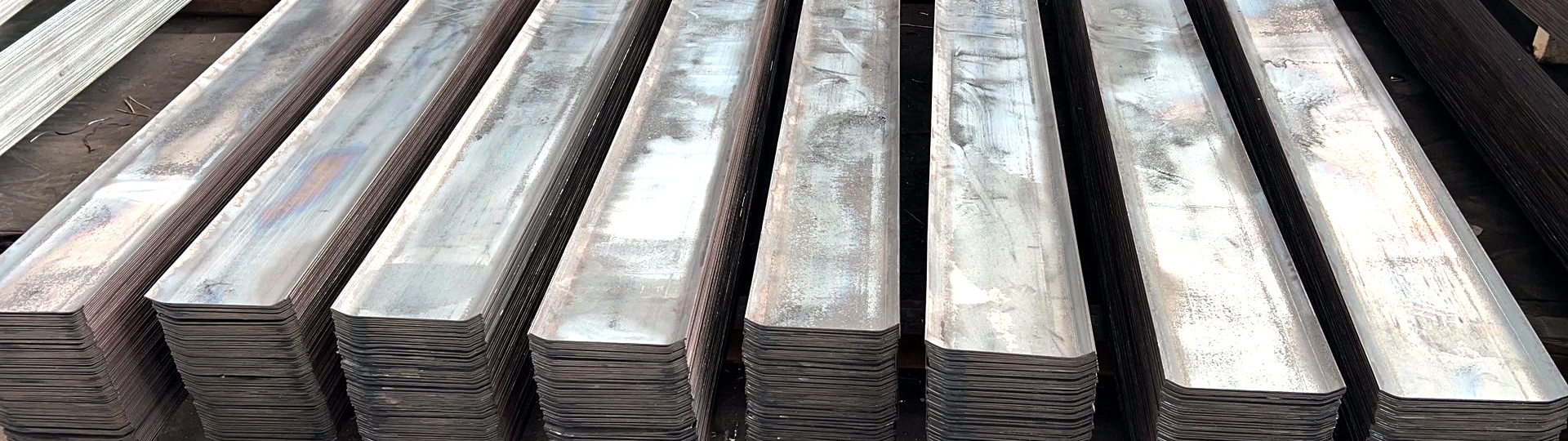

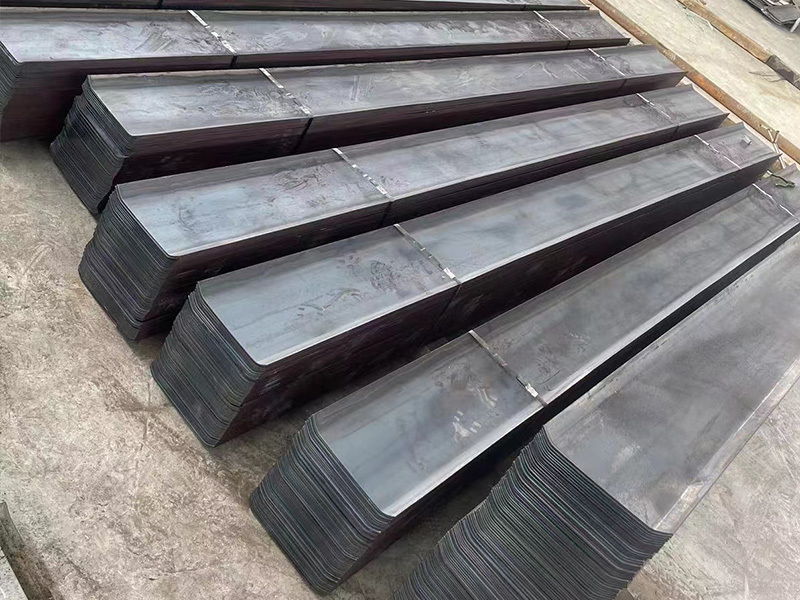

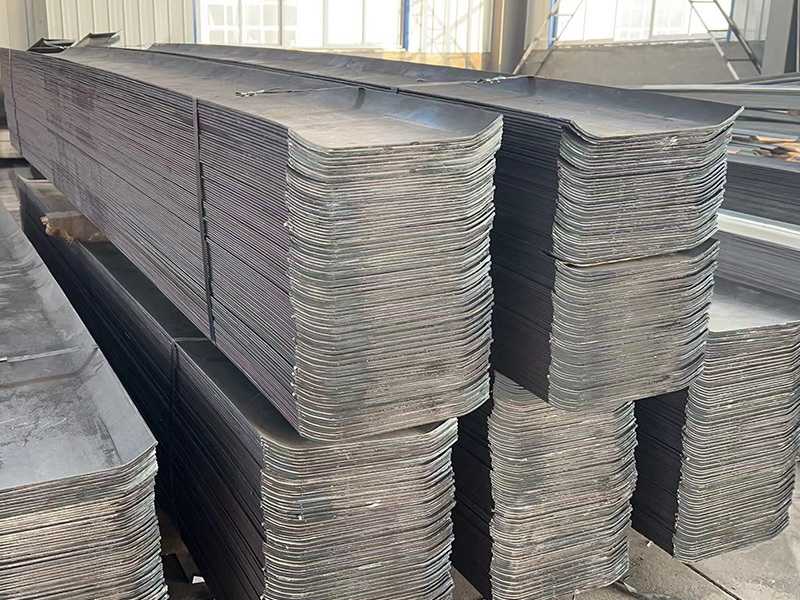

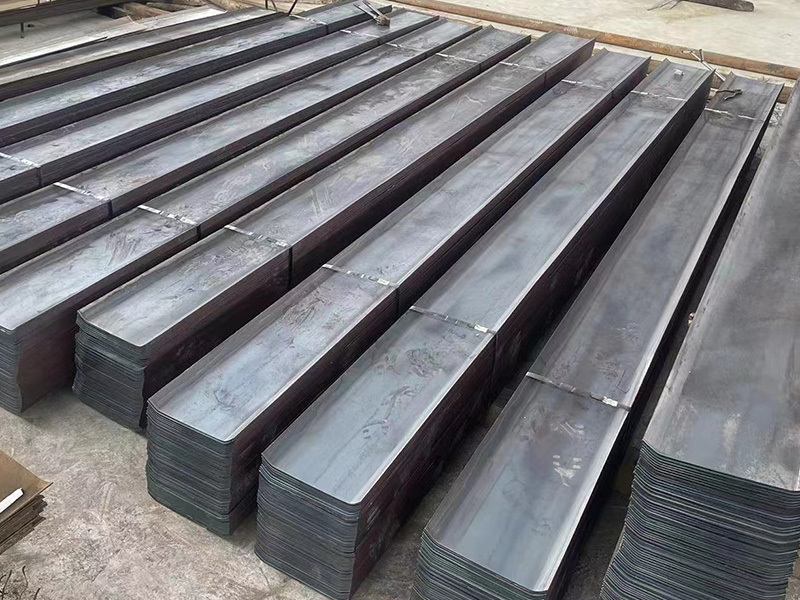

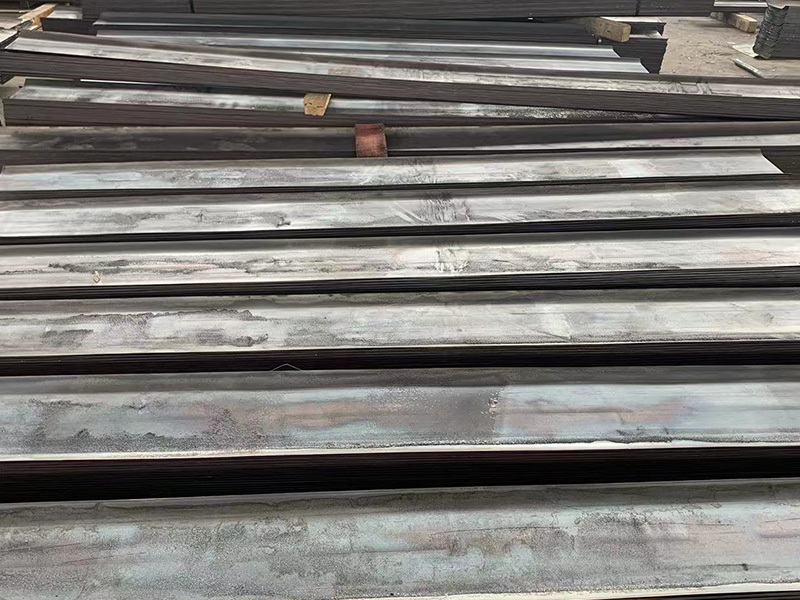

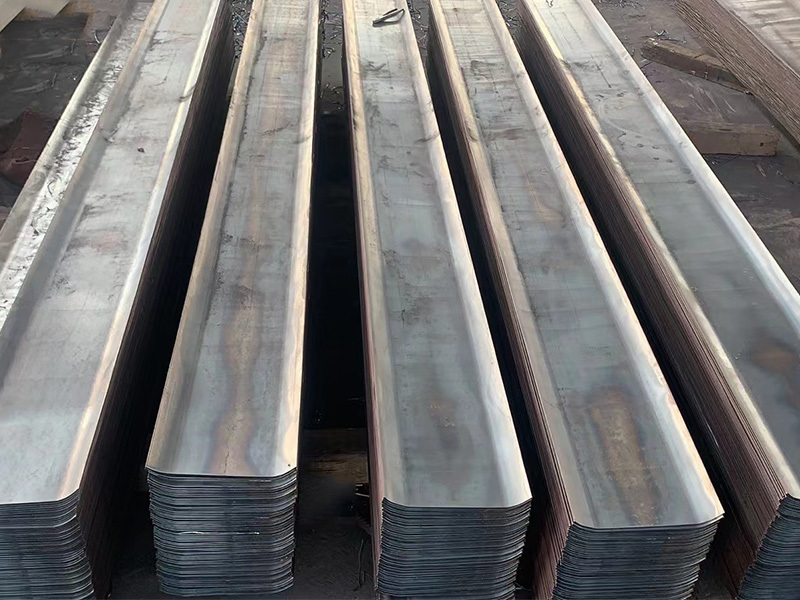

After the customized plan is determined, the supplier will produce and process according to the requirements. This includes a series of processes such as raw material procurement, cutting, bending, welding, and surface treatment. In the production process, the supplier should strictly control the quality to ensure that the water seal meets the relevant standards and requirements.

In the process of use, if you encounter any problems or need technical support, the supplier should provide timely after-sales service. This includes product consultation, troubleshooting, maintenance and replacement. Good after-sales service will provide customers with better experience and protection.

In the process of use, if you encounter any problems or need technical support, the supplier should provide timely after-sales service. This includes product consultation, troubleshooting, maintenance and replacement. Good after-sales service will provide customers with better experience and protection.

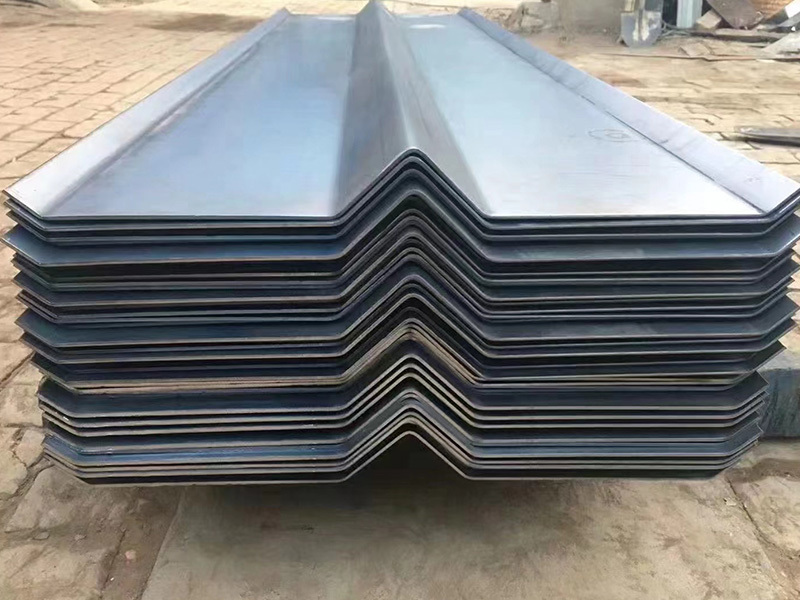

Curved steel plates, due to their unique shape and excellent physical properties, are indeed widely used in waterproofing projects with many special shapes and needs, especially in round pools, park landscapes, and situations requiring highly customized waterproofing solutions.

Waterproof isolation: The main function of the water seal plate is to prevent water flow through the structural gap to ensure the waterproof effect of the building or project.

Reinforcement support: In addition to waterproof function, sealing steel plate can also provide strong support and stability, withstand greater water pressure and earth pressure.

Made of carbon steel Q235B strip steel, after machine molding, cutting, processing customized, with good waterproof effect

Definition: Water sealing steel plate is a special component used in building basements, subway tunnels, underground pipelines and other projects to prevent water flow through structural gaps.

Application: Widely used in water conservancy engineering (such as DAMS, reservoirs), underground engineering (such as subway tunnels, underground garages), construction engineering (such as basements, underground parking lots) and traffic engineering (such as Bridges, tunnels) and other fields.

Clear demand: Before the purchase of water seal steel plate, the specific needs and specifications of the project should be clear.

Choose brand: Give priority to products produced by well-known brands and reputable manufacturers to ensure product quality and after-sales service.

Compare prices: Compare prices among multiple suppliers and choose products with higher cost performance.

Check the qualification: Check the supplier's qualification certificate and test report and other documents to ensure that the product meets the relevant standards and requirements.

In short, the ordinary sealing steel plate plays an important waterproof and supporting role in the project, and the purchase should be considered according to the actual demand and market conditions.

Due to the different factors such as the material, specifications, brand and market supply and demand of the sealing steel plate, its price will also be different. According to the recent market quotation, the price of ordinary sealing steel plate is roughly a few dollars to dozens of dollars per meter. The specific price needs to be determined according to the actual demand and market conditions.

Made of carbon steel Q235B strip steel, after machine molding, cutting, processing customized, with good waterproof effect

The specifications and sizes of the copper sealing plate are diverse to meet the needs of different projects. Generally speaking, its thickness ranges between 0.5-5mm, the width can reach 1000mm, and the length can reach 15000mm. In addition, the tensile strength of the copper water seal is not less than 240Mpa, the elongation is not less than 30%, and its chemical composition and physical properties must meet the provisions of relevant national standards.